ʻŌlelo Pōkole: Ua wehewehe pōkole ʻia ke kumumanaʻo hoʻopili ʻana, ka hoʻokaʻawale ʻana, ka hoʻokumu ʻana, ke kaʻina hana a me nā lako o ka mea hoʻokaʻawale polyethylene cross-linked silane no ka uea a me ke kaula, a ua hoʻolauna ʻia kekahi mau ʻano o ka mea hoʻokaʻawale polyethylene cross-linked silane ma ke ʻano kūlohelohe i ka hoʻohana ʻana a me ka hoʻohana ʻana a me nā mea e pili ana i ke kūlana hoʻopili ʻana o ka mea.

Nā huaʻōlelo: Hoʻopili ʻana o Silane; Hoʻopili kūlohelohe; Polyethylene; Hoʻopaʻa ʻana; Uea a me ke kaula

I kēia manawa, ua hoʻohana nui ʻia ka mea uwea polyethylene i hoʻopili ʻia me ke silane i ka ʻoihana uea a me ke kaula ma ke ʻano he mea hoʻokaʻawale no nā uwea mana haʻahaʻa. ʻO ka mea i ka hana ʻana o ke uea a me ke kaula i hoʻopili ʻia me ke keʻa, a me ka peroxide cross-linking a me ka irradiation cross-linking i hoʻohālikelike ʻia me nā lako hana e pono ai, he maʻalahi, maʻalahi e hana, haʻahaʻa ke kumukūʻai piha a me nā pono ʻē aʻe, ua lilo i mea alakaʻi no ke uwea i hoʻopili ʻia me ka insulation me ke keʻa haʻahaʻa voltage.

1.Kumumanaʻo hoʻopili ʻana o nā mea uwea i hoʻopili ʻia me ka silane

ʻElua mau kaʻina hana nui e pili ana i ka hana ʻana i ka polyethylene cross-linked silane: grafting a me ke cross-linking. I ke kaʻina hana grafting, nalowale ka polymer i kona H-atom ma ka atom kalapona tertiary ma lalo o ka hana a ka mea hoʻomaka manuahi a me ka pyrolysis i loko o nā radicals manuahi, e hana pū me ka hui – CH = CH2 o vinyl silane e hana i kahi polymer grafted e loaʻa ana kahi hui trioxysilyl ester. I ke kaʻina hana cross-linking, ua hydrolyzed mua ʻia ka polymer graft i ke alo o ka wai e hana i ka silanol, a hui pū ka – OH me ka hui Si-OH e pili ana e hana i ka pilina Si-O-Si, no laila e cross-linking i nā macromolecules polymer.

2. ʻO ka mea uwea i hoʻopili ʻia ʻo Silane a me kāna ʻano hana uwea

E like me kou ʻike, aia nā ʻano hana hana ʻelua-ʻanuʻu a me hoʻokahi-ʻanuʻu no nā kaula silane cross-linked a me kā lākou mau kaula. ʻO ka ʻokoʻa ma waena o ke ʻano ʻelua-ʻanuʻu a me ke ʻano hoʻokahi-ʻanuʻu aia ma kahi e hana ʻia ai ke kaʻina hana silane grafting, ke kaʻina hana grafting ma ka mea hana mea kaula no ke ʻano ʻelua-ʻanuʻu, ke kaʻina hana grafting ma ka hale hana hana kaula no ke ʻano hoʻokahi-ʻanuʻu. ʻO ka mea hoʻokaʻawale polyethylene cross-linked silane ʻelua-ʻanuʻu me ka māhele mākeke nui loa i haku ʻia me nā mea i kapa ʻia ʻo A a me B, me ka mea A ʻo ia ka polyethylene i grafted me ka silane a ʻo ka mea B ʻo ia ka catalyst master batch. A laila hoʻopili ʻia ke kumu insulating i ka wai mahana a i ʻole ka mahu.

Aia kekahi ʻano ʻē aʻe o ka insulator polyethylene cross-linked silane ʻelua-ʻanuʻu, kahi i hana ʻia ai ka mea A ma ke ʻano ʻokoʻa, ma ka hoʻolauna ʻana i ka vinyl silane pololei i loko o ka polyethylene i ka wā o ka synthesis e loaʻa ai ka polyethylene me nā kaulahao lālā silane.

ʻElua ʻano o ke ʻano hana hoʻokahi-ʻanuʻu, ʻo ke kaʻina hana hoʻokahi-ʻanuʻu kuʻuna he ʻano mea maka like ʻole e like me ke ʻano ma ka lakio o ka ʻōnaehana ana kikoʻī kūikawā, i loko o kahi extruder kūikawā i hoʻolālā kūikawā ʻia i hoʻokahi ʻanuʻu e hoʻopau i ka grafting a me ka extrusion o ke kumu insulation uwea, i kēia kaʻina hana, ʻaʻohe granulation, ʻaʻohe pono no ke komo ʻana o ka mea hana uwea, e ka hale hana uwea e hoʻopau wale. ʻO kēia mau lako hana uwea cross-linked silane hoʻokahi-ʻanuʻu a me ka ʻenehana formulation e lawe nui ʻia mai nā ʻāina ʻē a he pipiʻi.

ʻO kekahi ʻano o ka mea hoʻokaʻawale polyethylene cross-linked silane hoʻokahi-ʻanuʻu i hana ʻia e nā mea hana mea kaula, ʻo ia nā mea maka āpau e like me ke ʻano hana kūikawā o ka hui pū ʻana, ka hoʻopili ʻana a me ke kūʻai aku ʻana, ʻaʻohe mea A a me ka mea B, hiki ke hoʻokomo pololei ʻia ke kaula i loko o ka extruder e hoʻopau i kahi ʻanuʻu i ka manawa like e hoʻopili ai a hoʻokuʻu i ke kumu hoʻokaʻawale kaula. ʻO ka hiʻohiʻona kū hoʻokahi o kēia ʻano hana, ʻaʻohe pono no nā extruders kūikawā pipiʻi, no ka mea, hiki ke hoʻopau ʻia ke kaʻina hana hoʻopili silane i loko o kahi extruder PVC maʻamau, a hoʻopau ke ʻano hana ʻelua-ʻanuʻu i ka pono e kāwili i nā mea A a me B ma mua o ka hoʻokuʻu ʻana.

3. Hoʻohuihui ʻana

ʻO ka hoʻohui ʻana o ka mea kaula polyethylene i hoʻopili ʻia me ke silane i hana ʻia me ka resin mea kumu, mea hoʻomaka, silane, antioxidant, polymerization inhibitor, catalyst, etc.

(1) ʻO ka resin kumu ma ke ʻano maʻamau he resin polyethylene haʻahaʻa haʻahaʻa (LDPE) me kahi helu hoʻoheheʻe (MI) o 2, akā i kēia manawa, me ka hoʻomohala ʻana o ka ʻenehana resin synthetic a me nā kaomi kumukūʻai, ua hoʻohana ʻia ka linear low density polyethylene (LLDPE) a i ʻole hoʻohana hapa ʻia ma ke ʻano he resin kumu no kēia mea. Loaʻa pinepine ka hopena koʻikoʻi o nā resins like ʻole i ka grafting a me ke cross-linking ma muli o nā ʻokoʻa o kā lākou macromolecular structure kūloko, no laila e hoʻololi ʻia ke ʻano ma ka hoʻohana ʻana i nā resins kumu like ʻole a i ʻole ke ʻano like o ka resin mai nā mea hana like ʻole.

(2) ʻO ka mea hoʻomaka i hoʻohana pinepine ʻia ʻo diisopropyl peroxide (DCP), ʻo ke kī ke hoʻomaopopo i ka nui o ka pilikia, ʻaʻole lawa ka liʻiliʻi e hoʻoulu ai i ka silane grafting; ʻoi aku ka nui e hoʻoulu ai i ka polyethylene cross-linking, kahi e hoʻemi ai i kona wai, ʻo ka ʻili o ke kumu insulation extruded ʻinoʻino, paʻakikī ke ʻomi i ka ʻōnaehana. ʻOiai he liʻiliʻi loa a koʻikoʻi ka nui o ka mea hoʻomaka i hoʻohui ʻia, he mea nui e hoʻopuehu like iā ia, no laila ua hoʻohui pinepine ʻia me ka silane.

(3) Hoʻohana nui ʻia ka silane vinyl unsaturated silane, me ka vinyl trimethoxysilane (A2171) a me ka vinyl triethoxysilane (A2151), ma muli o ka wikiwiki o ka hydrolysis o A2171, no laila koho nui ʻia ʻo A2171. Pēlā nō, aia kahi pilikia o ka hoʻohui ʻana i ka silane, ke hoʻāʻo nei nā mea hana mea kaula o kēia manawa e hoʻokō i kona palena haʻahaʻa e hōʻemi i nā kumukūʻai, no ka mea, ua lawe ʻia mai nā silane, ʻoi aku ke kumukūʻai.

(4) ʻO ka Anti-oxidant ka mea e hōʻoia i ke kūpaʻa o ka hana polyethylene a me ke kaula anti-aging a hoʻohui ʻia, ʻo ka anti-oxidant i ke kaʻina hana grafting silane ke kuleana o ka pale ʻana i ka hopena grafting, no laila ke kaʻina hana grafting, ʻo ka hoʻohui ʻana o ka anti-oxidant e makaʻala, ʻo ka nui i hoʻohui ʻia e noʻonoʻo i ka nui o DCP e kūlike i ke koho. I ke kaʻina hana cross-linking ʻelua-ʻanuʻu, hiki ke hoʻohui ʻia ka hapa nui o ka antioxidant i loko o ka catalyst master batch, hiki ke hōʻemi i ka hopena ma ke kaʻina hana grafting. I ke kaʻina hana cross-linking hoʻokahi-ʻanuʻu, aia ka antioxidant i ke kaʻina hana grafting holoʻokoʻa, no laila ʻoi aku ka nui o ke koho ʻana o nā ʻano a me ka nui. ʻO nā antioxidants i hoʻohana pinepine ʻia he 1010, 168, 330, etc.

(5) Hoʻohui ʻia ka mea hoʻopaʻa polymerization i mea e kāohi ai i kekahi mau hana hoʻopili a me ke kaʻina hana cross-linking o nā hopena ʻaoʻao e hana ʻia, i ke kaʻina hana grafting e hoʻohui i kahi mea anti-cross-linking, hiki ke hoʻemi pono i ka hanana o ka C2C cross-linking, a laila e hoʻomaikaʻi ana i ka fluidity hana, a eia kekahi, ʻo ka hoʻohui ʻana o kahi graft ma nā kūlana like e hele mua ʻia e ka hydrolysis o ka silane ma luna o ka polymerization inhibitor hiki ke hoʻemi i ka hydrolysis o ka polyethylene grafted, e hoʻomaikaʻi i ke kūpaʻa lōʻihi o ka mea graft.

(6) ʻO nā mea hoʻouluulu pinepine he mau mea hoʻouluulu organotin (koe wale nō ka crosslinking kūlohelohe), ʻo ka mea maʻamau ka dibutyltin dilaurate (DBDTL), kahi i hoʻohui pinepine ʻia ma ke ʻano o kahi masterbatch. Ma ke kaʻina hana ʻelua-ʻanuʻu, ua hoʻopili ʻokoʻa ʻia ka graft (mea A) a me ka catalyst master batch (mea B) a ua hui pū ʻia nā mea A a me B ma mua o ka hoʻohui ʻia ʻana i ka extruder e pale aku i ka pre-crosslinking o ka mea A. I ke ʻano o nā insulations polyethylene cross-linked silane hoʻokahi-ʻanuʻu, ʻaʻole i hoʻopili ʻia ka polyethylene i loko o ka pūʻolo, no laila ʻaʻohe pilikia pre-cross-linking a no laila ʻaʻole pono e hoʻopili ʻokoʻa ʻia ka catalyst.

Eia kekahi, aia nā silanes i hoʻohui ʻia ma ka mākeke, ʻo ia ka hui pū ʻana o ka silane, ka mea hoʻomaka, ka antioxidant, kekahi mau lubricants a me nā mea anti-copper, a hoʻohana nui ʻia i nā ʻano hana hoʻopili silane hoʻokahi-ʻanuʻu i nā mea kanu kaula.

No laila, ʻo ka hoʻokumu ʻana o ka silane cross-linked polyethylene insulation, ka haku mele ʻana o ia mea ʻaʻole i manaʻo ʻia he paʻakikī loa a loaʻa i ka ʻike pili, akā ʻo nā ʻano hana kūpono, e pili ana i kekahi mau hoʻoponopono i mea e hoʻopau ai, e koi ana i ka hoʻomaopopo piha ʻana i ke kuleana o nā ʻāpana i ka hoʻokumu ʻana a me ke kānāwai o ko lākou hopena i ka hana a me ko lākou mana like.

I loko o nā ʻano mea uwea he nui, ʻo ka mea uwea silane cross-linked (ʻelua-ʻanuʻu a i ʻole hoʻokahi-ʻanuʻu) i manaʻo ʻia ʻo ia wale nō ke ʻano o nā kaʻina hana kemika e hana ʻia ana i ka extrusion, ʻo nā ʻano ʻē aʻe e like me ka polyvinyl chloride (PVC) mea uwea a me ka polyethylene (PE) mea uwea, ʻo ke kaʻina hana extrusion granulation he kaʻina hana hui kino, ʻoiai inā ʻo ka keʻa keʻa keʻa a me ka irradiation cross-linking mea uwea, inā paha i loko o ke kaʻina hana extrusion granulation, a i ʻole ka ʻōnaehana extrusion Cable, ʻaʻohe kaʻina hana kemika e hana ʻia, no laila, i ka hoʻohālikelike ʻana, ʻoi aku ka nui o ka mana o ke kaʻina hana no ka hana ʻana o ka silane cross-linked mea uwea a me ka extrusion insulation uwea.

4. Ke kaʻina hana hana insulation polyethylene cross-linked silane ʻelua-ʻanuʻu

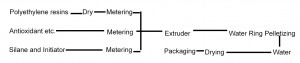

Hiki ke hōʻike pōkole ʻia ke kaʻina hana o ka insulation polyethylene cross-linked silane ʻelua-ʻanuʻu A e ke Kiʻi 1.

Kiʻi 1 Ke kaʻina hana o ka mea hoʻokaʻawale polyethylene cross-linked silane ʻelua-ʻanuʻu A

ʻO kekahi mau kumu koʻikoʻi i ke kaʻina hana o ka insulation polyethylene cross-linked silane ʻelua-ʻanuʻu:

(1) Ka maloʻo ʻana. ʻOiai he liʻiliʻi ka wai o ka polyethylene resin, ke hoʻokuʻu ʻia i nā mahana kiʻekiʻe, pane koke ka wai me nā hui silyl e hana i ka cross-linking, kahi e hōʻemi ai i ke kahe o ka heheʻe a hana i ka pre-cross-linking. Loaʻa pū ka wai i ka mea i hoʻopau ʻia ma hope o ka hoʻomaʻalili ʻana o ka wai, hiki ke hana i ka pre-crosslinking inā ʻaʻole i wehe ʻia, a pono hoʻi e maloʻo. I mea e hōʻoia ai i ka maikaʻi o ka maloʻo ʻana, hoʻohana ʻia kahi ʻāpana maloʻo hohonu.

(2) Ana ʻana. No ka mea he mea nui ka pololei o ke ʻano o ka mea hana, hoʻohana pinepine ʻia kahi unahi kaupaona i lawe ʻia mai. Ana ʻia ka resin polyethylene a me ka antioxidant a hānai ʻia ma o ka puka hānai o ka extruder, ʻoiai ʻo ka silane a me ka mea hoʻomaka e hoʻokomo ʻia e kahi pamu mea wai i loko o ka lua a i ʻole ke kolu o ka barela o ka extruder.

(3) Hoʻopili ʻana i ka extrusion. Hoʻopau ʻia ke kaʻina hana hoʻopili o ka silane i loko o ka extruder. Pono nā hoʻonohonoho hana o ka extruder, me ka mahana, ka hui pū ʻana o nā wili, ka wikiwiki o nā wili a me ka wikiwiki o ka hānai ʻana, e hahai i ke kumumanaʻo e hiki ke hoʻoheheʻe piha ʻia a hui like ʻia ka mea ma ka ʻāpana mua o ka extruder, ke makemake ʻole ʻia ka palaho mua ʻana o ka peroxide, a pono e palaho piha ʻia ka mea like piha ma ka ʻāpana ʻelua o ka extruder a hoʻopau ʻia ke kaʻina hana hoʻopili. Hōʻike ʻia nā mahana maʻamau o ka ʻāpana extruder (LDPE) ma ka Papa 1.

Papa 1 Nā mahana o nā ʻāpana extruder ʻelua-ʻanuʻu

| ʻĀpana hana | ʻĀpana 1 | ʻĀpana 2 | ʻĀpana 3 ① | ʻĀpana 4 | ʻĀpana 5 |

| Mahana P °C | 140 | 145 | 120 | 160 | 170 |

| ʻĀpana hana | ʻĀpana 6 | ʻĀpana 7 | ʻĀpana 8 | ʻĀpana 9 | Make waha |

| Mahana °C | 180 | 190 | 195 | 205 | 195 |

①ʻo ia kahi i hoʻohui ʻia ai ka silane.

ʻO ka wikiwiki o ka wili extruder e hoʻoholo i ka manawa noho a me ka hopena hui ʻana o ka mea i loko o ka extruder, inā pōkole ka manawa noho, ʻaʻole i piha ka peroxide decomposition; inā lōʻihi loa ka manawa noho, piʻi ka viscosity o ka mea i extruded. Ma keʻano laulā, pono e hoʻomalu ʻia ka awelika o ka manawa noho o ka granule i loko o ka extruder i ka hapalua ola decomposition initiator o 5-10 mau manawa. ʻAʻole wale ka wikiwiki o ka hānai ʻana i ka hopena i ka manawa noho o ka mea, akā, i ka hui ʻana a me ka ʻoki ʻana o ka mea, he mea nui loa ke koho ʻana i ka wikiwiki hānai kūpono.

(4) Pūʻolo. Pono e hoʻopili ʻia nā mea hoʻokaʻawale silane ʻelua-ʻanuʻu i loko o nā ʻeke hui alumini-plastic i ka ea pololei e hoʻopau i ka makū.

5. Kaʻina hana hana mea hoʻokaʻawale polyethylene cross-linked silane hoʻokahi ʻanuʻu

ʻO ka mea hoʻokaʻawale polyethylene cross-linked silane hoʻokahi-ʻanuʻu ma muli o kāna kaʻina hana grafting i loko o ka hale hana uwea extrusion o ke kumu insulation uwea, no laila ʻoi aku ka kiʻekiʻe o ka mahana extrusion insulation uwea ma mua o ke ʻano ʻelua-ʻanuʻu. ʻOiai ua noʻonoʻo piha ʻia ke ʻano hoʻokaʻawale polyethylene cross-linked silane hoʻokahi-ʻanuʻu i ka hoʻopuehu wikiwiki ʻana o ka mea hoʻomaka a me ka silane a me ka shear mea, akā pono e hōʻoia ʻia ke kaʻina hana grafting e ka mahana, ʻo ia ka hale hana hana hoʻokaʻawale polyethylene cross-linked silane hoʻokahi-ʻanuʻu i hoʻoikaika pinepine i ke koʻikoʻi o ke koho pololei ʻana o ka mahana extrusion, ua hōʻike ʻia ka mahana extrusion i ʻōlelo ʻia ma ka Papa 2.

Papa 2 Ka mahana o ka extruder hoʻokahi-ʻanuʻu o kēlā me kēia ʻāpana (unit: ℃)

| ʻĀpana | ʻĀpana 1 | ʻĀpana 2 | ʻĀpana 3 | ʻĀpana 4 | ʻO ke kāʻei | Poʻo |

| Mahana | 160 | 190 | 200~210 | 220~230 | 230 | 230 |

ʻO kēia kekahi o nā nāwaliwali o ke kaʻina hana polyethylene cross-linked silane hoʻokahi-ʻanuʻu, ʻaʻole pono ia i ka wā e hoʻopuka ai i nā kaula i ʻelua mau ʻanuʻu.

6. Nā lako hana

He mea nui ka lako hana no ka hoʻomalu ʻana i ke kaʻina hana. Pono ka hana ʻana i nā kaula silane cross-linked i kahi kiʻekiʻe loa o ka pololei o ka hoʻomalu ʻana i ke kaʻina hana, no laila he mea nui loa ke koho ʻana i nā lako hana.

ʻO ka hana ʻana o nā mea hana insulation polyethylene cross-linked silane ʻelua-ʻanuʻu A, i kēia manawa ʻoi aku ka nui o ka isotropic parallel twin-screw extruder me ka kaupaona kaumaha i lawe ʻia mai, hiki i kēlā mau mea hana ke hoʻokō i nā koi o ka pololei o ke kaʻina hana, ke koho ʻana o ka lōʻihi a me ke anawaena o ka extruder twin-screw e hōʻoia i ka manawa noho o ka mea, ke koho ʻana o ka kaupaona kaumaha i lawe ʻia mai e hōʻoia i ka pololei o nā mea hoʻohui. ʻOiaʻiʻo, he nui nā kikoʻī o nā lako e pono e hāʻawi ʻia i ka nānā piha.

E like me ka mea i ʻōlelo ʻia ma mua, ua lawe ʻia mai nā lako hana uwea hoʻokahi-ʻanuʻu silane i loko o ka hale hana uwea, he pipiʻi, ʻaʻohe lako hana like o nā mea hana lako kūloko, ʻo ke kumu no ka nele o ka laulima ma waena o nā mea hana lako a me nā mea noiʻi formula a me ke kaʻina hana.

7. Silane mea hoʻokaʻawale polyethylene cross-linked kūlohelohe

Hiki ke hoʻopili ʻia ka mea hoʻokaʻawale polyethylene cross-linked kūlohelohe Silane i hoʻomohala ʻia i nā makahiki i hala iho nei ma lalo o nā kūlana kūlohelohe i loko o kekahi mau lā, me ka ʻole o ka mahu a i ʻole ka hoʻoluʻu wai mahana. Ke hoʻohālikelike ʻia me ke ʻano hoʻopili silane kuʻuna, hiki i kēia mea ke hōʻemi i ke kaʻina hana no nā mea hana kaula, e hōʻemi hou ana i nā kumukūʻai hana a hoʻonui i ka pono hana. ʻIke nui ʻia a hoʻohana ʻia ka insulation polyethylene cross-linked kūlohelohe Silane e nā mea hana kaula.

I nā makahiki i hala iho nei, ua oʻo ka insulation polyethylene cross-linked natural silane kūloko a ua hana ʻia i nā nui he nui, me kekahi mau pono i ke kumukūʻai hoʻohālikelike ʻia me nā mea i lawe ʻia mai.

7. 1 Nā manaʻo hoʻokumu no nā insulations polyethylene cross-linked silane kūlohelohe

Hana ʻia nā insulations polyethylene cross-linked kūlohelohe Silane ma ke kaʻina hana ʻelua-ʻanuʻu, me ke ʻano like i loaʻa i ka resin kumu, ka mea hoʻomaka, silane, antioxidant, polymerisation inhibitor a me ka catalyst. Hoʻokumu ʻia ke ʻano o nā insulators polyethylene cross-linked kūlohelohe silane ma ka hoʻonui ʻana i ka helu grafting silane o ka mea A a me ke koho ʻana i kahi catalyst ʻoi aku ka maikaʻi ma mua o nā insulators polyethylene cross-linked wai mahana silane. ʻO ka hoʻohana ʻana i nā mea A me ka helu grafting silane kiʻekiʻe i hui pū ʻia me kahi catalyst ʻoi aku ka maikaʻi e hiki ai i ka insulator polyethylene cross-linked silane ke cross-link wikiwiki i nā mahana haʻahaʻa a me ka lawa ʻole o ka makū.

Hoʻohui ʻia nā mea A no nā silane i lawe ʻia mai i lawe ʻia mai me nā mea hoʻokaʻawale polyethylene i hoʻopili ʻia ma ke ʻano kūlohelohe e ka copolymerization, kahi e hiki ai ke hoʻomalu ʻia ka nui o ka silane ma kahi kiʻekiʻe, ʻoiai he paʻakikī ka hana ʻana o nā mea A me nā helu grafting kiʻekiʻe ma o ka grafting silane. Pono e hoʻololi ʻia a hoʻoponopono ʻia ke kumu resin, ka mea hoʻomaka a me ka silane i hoʻohana ʻia i loko o ke ʻano hana ma ke ʻano o nā ʻano like ʻole a me ka hoʻohui.

He mea koʻikoʻi nō hoʻi ke koho ʻana o ke kū'ē a me ka hoʻoponopono ʻana i kona nui, ʻoiai ʻo ka piʻi ʻana o ka helu grafting o ka silane e alakaʻi mau ana i nā hopena ʻaoʻao crosslinking CC hou aʻe. I mea e hoʻomaikaʻi ai i ka wai hana a me ke kūlana o ka ʻili o ka mea A no ka extrusion kaula ma hope, pono ka nui kūpono o ka mea hoʻopaʻa polymerization e kāohi pono i ka crosslinking CC a me ka pre-crosslinking mua.

Eia kekahi, he kuleana koʻikoʻi nā mea hoʻoulu i ka hoʻonui ʻana i ka helu crosslinking a pono e koho ʻia he mau mea hoʻoulu kūpono e loaʻa ana nā mea metala ʻole hoʻololi.

7. 2 Ka manawa hoʻopili ʻana o nā insulations polyethylene crosslinked silane kūlohelohe

ʻO ka manawa e pono ai e hoʻopau i ke kāpili ʻana o ka silane natural cross-linked polyethylene insulation i kona kūlana maoli e pili ana i ka mahana, ka makū a me ka mānoanoa o ka papa insulation. ʻO ke kiʻekiʻe o ka mahana a me ka makū, ʻoi aku ka lahilahi o ka mānoanoa o ka papa insulation, ʻoi aku ka pōkole o ka manawa crosslinking e pono ai, a ʻoi aku ka lōʻihi o ke kū'ē. Ma muli o ka ʻokoʻa o ka mahana a me ka makū mai kēlā ʻāina a i kēia ʻāina a mai kēlā kau a i kēia kau, ʻoiai ma kahi like a i ka manawa like, e ʻokoʻa ka mahana a me ka makū i kēia lā a me ka lā ʻapōpō. No laila, i ka wā e hoʻohana ai i ka mea, pono ka mea hoʻohana e hoʻoholo i ka manawa cross-linking e like me ka mahana a me ka makū kūloko a me ka mea e kū nei, a me ke kikoʻī o ke kaula a me ka mānoanoa o ka papa insulation.

Ka manawa hoʻouna: Aug-13-2022