Me he mea lā maʻalahi ke ʻano o ke kaula, ʻo ka ʻoiaʻiʻo, he kumu koʻikoʻi ko kēlā me kēia ʻāpana, no laila pono e koho pono ʻia kēlā me kēia ʻāpana i ka wā e hana ai i ke kaula, i mea e hōʻoia ai i ka hilinaʻi o ke kaula i hana ʻia me kēia mau mea i ka wā e hana ai.

1. Mea alakaʻi

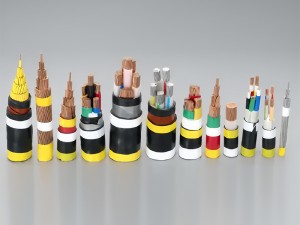

I ka wā ma mua, ʻo nā mea i hoʻohana ʻia no nā alakaʻi uwea mana he keleawe a me ka alumini. Ua hoʻāʻo pōkole ʻia hoʻi ka sodium. ʻOi aku ka maikaʻi o ka conductivity uila o ke keleawe a me ka alumini, a ʻoi aku ka liʻiliʻi o ka nui o ke keleawe i ka wā e hoʻoili ana i ke au like, no laila ʻoi aku ka liʻiliʻi o ke anawaena o waho o ke alakaʻi keleawe ma mua o ke alakaʻi alumini. ʻOi aku ka haʻahaʻa o ke kumukūʻai o ka alumini ma mua o ke keleawe. Eia kekahi, no ka mea ʻoi aku ka nui o ke keleawe ma mua o ka alumini, ʻoiai inā like ka hiki ke lawe i ke au, ʻoi aku ka nui o ka ʻāpana kea o ke alakaʻi alumini ma mua o ke alakaʻi keleawe, akā ʻoi aku ka māmā o ke kaula alakaʻi alumini ma mua o ke kaula alakaʻi keleawe.

2. Nā mea hoʻokaʻawale

Nui nā mea hoʻokaʻawale e hiki ai i nā kaula mana MV ke hoʻohana, me nā mea hoʻokaʻawale pepa i hoʻopaʻa ʻia i ka ʻenehana, i hoʻohana pono ʻia no nā makahiki he 100 a ʻoi. I kēia lā, ua ʻae nui ʻia ka hoʻokaʻawale polymer extruded. ʻO nā mea hoʻokaʻawale polymer extruded e komo pū me PE (LDPE a me HDPE), XLPE, WTR-XLPE a me EPR. He thermoplastic kēia mau mea a me thermosetting. Hoʻololi nā mea thermoplastic i ka wā e hoʻomehana ʻia ai, ʻoiai nā mea thermoset e mālama i ko lākou ʻano i nā mahana hana.

2.1. Hoʻopaʻa pepa

I ka hoʻomaka ʻana o kā lākou hana, he liʻiliʻi wale nō ka ukana o nā kaula i hoʻopaʻa ʻia me ka pepa a mālama pono ʻia. Eia nō naʻe, ke hoʻomau nei nā mea hoʻohana mana i ka hana ʻana i ke kaula e halihali ana i ka ukana kiʻekiʻe aʻe, ʻaʻole kūpono hou nā kūlana hoʻohana mua no nā pono o ke kaula o kēia manawa, a laila ʻaʻole hiki i ka ʻike maikaʻi mua ke hōʻike i ka hana o ke kaula i ka wā e hiki mai ana. I nā makahiki i hala iho nei, ua hoʻohana pinepine ʻia nā kaula i hoʻopaʻa ʻia me ka pepa.

2.2.PVC

Hoʻohana mau ʻia ʻo PVC ma ke ʻano he mea hoʻokaʻawale no nā kaula 1kV haʻahaʻa haʻahaʻa a he mea uhi hoʻi. Eia nō naʻe, ke pani koke ʻia nei ka hoʻohana ʻana o PVC i ka insulation uwea e XLPE, a ke pani koke ʻia nei ka hoʻohana ʻana i loko o ka sheath e ka linear low density polyethylene (LLDPE), medium density polyethylene (MDPE) a i ʻole high density polyethylene (HDPE), a ʻoi aku ka haʻahaʻa o ke kumukūʻai o ke ola o nā kaula ʻaʻole PVC.

2.3. Polyethylene (PE)

Ua hoʻomohala ʻia ka polyethylene haʻahaʻa haʻahaʻa (LDPE) i nā makahiki 1930 a ua hoʻohana ʻia i kēia manawa ma ke ʻano he resin kumu no ka polyethylene crosslinked (XLPE) a me nā mea polyethylene crosslinked lāʻau pale wai (WTR-XLPE). I ke kūlana thermoplastic, ʻo ka mahana hana kiʻekiʻe loa o ka polyethylene he 75 ° C, ʻoi aku ka haʻahaʻa ma mua o ka mahana hana o nā kaula pepa insulated (80 ~ 90 ° C). Ua hoʻoponopono ʻia kēia pilikia me ka hiki ʻana mai o ka polyethylene cross-linked (XLPE), hiki ke hoʻokō a ʻoi aku paha i ka mahana lawelawe o nā kaula pepa-insulated.

2.4.ʻO ka polyethylene i hoʻopili ʻia (XLPE)

He mea thermosetting ka XLPE i hana ʻia ma ke kāwili ʻana i ka polyethylene haʻahaʻa (LDPE) me kahi mea crosslinking (e like me ka peroxide).

ʻO ka mahana hana kiʻekiʻe loa o ke alakaʻi o ke kaula insulated XLPE he 90 ° C, ʻo ka hoʻāʻo overload a hiki i ka 140 ° C, a hiki i ka mahana pōkole ke piʻi i 250 ° C. Loaʻa iā XLPE nā ʻano dielectric maikaʻi loa a hiki ke hoʻohana ʻia i ka pae voltage o 600V a 500kV.

2.5. ʻO ka polyethylene cross-linked lāʻau kūpaʻa wai (WTR-XLPE)

E hōʻemi ana ka hanana lāʻau wai i ke ola lawelawe o ke kaula XLPE. Nui nā ala e hōʻemi ai i ka ulu ʻana o nā lāʻau wai, akā ʻo kekahi o nā mea i ʻae nui ʻia, ʻo ia ka hoʻohana ʻana i nā mea insulation i hana kūikawā ʻia e kāohi i ka ulu ʻana o nā lāʻau wai, i kapa ʻia ʻo ka polyethylene cross-linked lāʻau kū i ka wai ʻo WTR-XLPE.

2.6. ʻEthylene propylene rubber (EPR)

He mea thermosetting ʻo EPR i hana ʻia me ka ethylene, propylene (i kekahi manawa he monomer ʻekolu), a ʻo ka copolymer o nā monomers ʻekolu i kapa ʻia ʻo ethylene propylene diene rubber (EPDM). Ma luna o kahi laulā wela ākea, e palupalu mau ana ʻo EPR a he pale corona maikaʻi. Eia nō naʻe, ʻoi aku ka kiʻekiʻe o ka pohō dielectric o ka mea EPR ma mua o XLPE a me WTR-XLPE.

3. Ke kaʻina hana hoʻouluulu ʻana i ka insulation

ʻO ke kaʻina hana crosslinking he mea kūikawā ia i ka polymer i hoʻohana ʻia. Hoʻomaka ka hana ʻana o nā polymers crosslinked me kahi polymer matrix a laila hoʻohui ʻia nā mea hoʻopaʻa a me nā crosslinkers e hana i kahi hui. Hoʻohui ke kaʻina hana crosslinking i nā wahi pili hou aku i ka ʻano molekala. Ke hoʻopaʻa ʻia, noho elastic ke kaulahao molekala polymer, akā ʻaʻole hiki ke ʻoki loa ʻia i loko o kahi wai heheʻe.

4. Nā mea pale a me nā mea pale hoʻokaʻawale no ke alakaʻi

Hoʻopuka ʻia ka papa pale semi-conductive ma luna o ka ʻili waho o ke alakaʻi a me ka insulation e hoʻohālikelike i ke kahua uila a e hoʻopaʻa i ke kahua uila i loko o ke kumu insulated uwea. Loaʻa i kēia mea kahi papa ʻenekinia o ka mea kalapona ʻeleʻele e hiki ai i ka papa pale o ke kaula ke hoʻokō i kahi conductivity paʻa i loko o ka pae i koi ʻia.

Ka manawa hoʻouna: ʻApelila-12-2024