Hoʻopilikia pololei ka hana o nā mea hoʻokaʻawale i ka maikaʻi, ka pono hana a me ka laulā o ka hoʻohana ʻana o nā uea a me nā kaula. Hoʻopilikia pololei ka hana o nā mea hoʻokaʻawale i ka maikaʻi, ka pono hana a me ka laulā o ka hoʻohana ʻana o nā uea a me nā kaula.

1.PVC polyvinyl chloride uea a me nā kaula

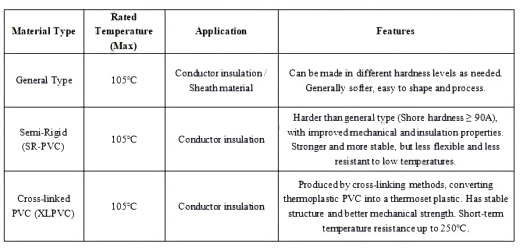

ʻO ka Polyvinyl chloride (i kapa ʻia ma hope aku nei ʻoPVC) nā mea hoʻokaʻawale he mau hui ʻana i hoʻohui ʻia ai nā mea hoʻopaʻa, nā plasticizer, nā mea pale ahi, nā lubricants a me nā mea hoʻohui ʻē aʻe i ka pauka PVC. Wahi a nā noi like ʻole a me nā koi ʻano o nā uea a me nā kaula, ua hoʻoponopono ʻia ke ʻano hana. Ma hope o nā makahiki he ʻumi o ka hana ʻana a me ka noi ʻana, ua lilo ka ʻenehana hana a me ka hana ʻana o PVC i mea oʻo loa. Loaʻa i nā mea hoʻokaʻawale PVC nā noi ākea loa ma ke kahua o nā uea a me nā kaula a he mau ʻano ʻokoʻa kona iho:

A. Ua oʻo ka ʻenehana hana ʻana, maʻalahi ke hana a hana. Ke hoʻohālikelike ʻia me nā ʻano mea hoʻokaʻawale uwea ʻē aʻe, ʻaʻole wale ke kumukūʻai haʻahaʻa, akā hiki ke hoʻomalu pono i ka ʻokoʻa kala, ka ʻōlinolino, ka paʻi ʻana, ka pono o ka hana ʻana, ka palupalu a me ka paʻakikī o ka ʻili uea, ka hoʻopili ʻana o ke alakaʻi, a me nā waiwai mechanical a me ke kino a me nā waiwai uila o ke uea ponoʻī.

B. He hana pale ahi maikaʻi loa ia, no laila hiki i nā uea PVC insulated ke hoʻokō maʻalahi i nā māka pale ahi i kau ʻia e nā kūlana like ʻole.

C. Ma ke ʻano o ke kūpaʻa ʻana i ka mahana, ma o ka hoʻonui ʻana a me ka hoʻomaikaʻi ʻana i nā ʻano mea, ʻo nā ʻano insulation PVC i hoʻohana nui ʻia i kēia manawa e komo pū me kēia mau ʻano ʻekolu:

Ma ke ʻano o ke ana uila i helu ʻia, hoʻohana nui ʻia ia i nā pae uila i helu ʻia ma 1000V AC a ma lalo, a hiki ke hoʻohana nui ʻia i nā ʻoihana e like me nā lako hale, nā mea kani a me nā mika, nā kukui, a me ke kamaʻilio pūnaewele.

Loaʻa iā PVC kekahi mau hemahema kūlohelohe e kaupalena ana i kāna noi:

A. Ma muli o kona nui o ka chlorine, e hoʻokuʻu ia i ka nui o ka uahi mānoanoa i ka wā e puhi ai, hiki ke hoʻoulu i ka hanu ʻana, hoʻopilikia i ka ʻike ʻana, a hana i kekahi mau carcinogens a me ke kinoea HCl, e hōʻeha nui ana i ke kaiapuni. Me ka hoʻomohala ʻana o ka ʻenehana hana mea insulation halogen haʻahaʻa haʻahaʻa, ua lilo ka hoʻololi mālie ʻana i ka insulation PVC i mea hiki ʻole ke pale ʻia i ka hoʻomohala ʻana i nā kaula.

B. ʻO ka pale ʻana o ka PVC maʻamau he haʻahaʻa i ke kūpaʻa ʻana i nā waikawa a me nā alkalis, ka ʻaila wela, a me nā mea hoʻoheheʻe organik. Wahi a ke kumumanaʻo kemika o nā mea like e hoʻoheheʻe like, he maʻalahi loa nā uea PVC i ka hōʻino a me ka haki ʻana i ke kaiapuni kikoʻī i ʻōlelo ʻia. Eia naʻe, me kāna hana hana maikaʻi loa a me ke kumukūʻai haʻahaʻa. Hoʻohana nui ʻia nā uea PVC i nā lako hale, nā kukui uila, nā lako mīkini, nā mea kani a me nā mika, ke kamaʻilio pūnaewele, nā uea hale a me nā ʻoihana ʻē aʻe.

2. Nā uea a me nā kaula polyethylene i hoʻopili ʻia

PE i hoʻopili ʻia (e kapa ʻia ma hope aku neiXLPE) he ʻano polyethylene ia e hiki ke hoʻololi mai kahi ʻano molekala linear i kahi ʻano ʻekolu-dimensional ma lalo o kekahi mau kūlana ma lalo o ka hana a nā kukuna ikehu kiʻekiʻe a i ʻole nā mea hoʻopili keʻa. I ka manawa like, hoʻololi ia mai ka thermoplastic i ka plastic thermosetting insoluble.

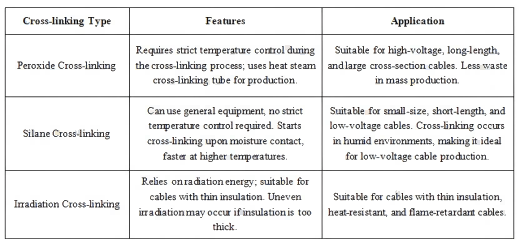

I kēia manawa, i ka hoʻohana ʻana i ka insulation uea a me ke kaula, aia ʻekolu mau ʻano hana cross-linking:

A. Ke hoʻopili ʻana i ka peroxide: Pili ia i ka hoʻohana mua ʻana i ka polyethylene resin i hui pū ʻia me nā mea hoʻopili kūpono a me nā antioxidants, a laila hoʻohui i nā ʻāpana ʻē aʻe e like me ka mea e pono ai e hana i nā ʻāpana hui polyethylene hiki ke hoʻopili ʻia. I ka wā o ke kaʻina hana extrusion, hana ʻia ke hoʻopili ʻana ma o nā paipu hoʻopili mahu wela.

B. Ke hoʻopili ʻana o Silane (ke hoʻopili ʻana i ka wai mahana): He ʻano hana kēia no ka hoʻopili ʻana i ka kemika. ʻO kāna ʻano hana nui ka hoʻopili ʻana i ka organosiloxane a me ka polyethylene ma lalo o nā kūlana kikoʻī, a

a ʻo ke kekelē o ka cross-linking hiki ke hiki ma kahi o 60%.

C. Hoʻopili ʻana i ka irradiation: Hoʻohana ia i nā kukuna ikehu kiʻekiʻe e like me nā kukuna R, nā kukuna alpha, a me nā kukuna electron e hoʻoulu i nā ʻātoma kalapona i loko o nā polyethylene macromolecules a hana i ka hoʻopili ʻana. ʻO nā kukuna ikehu kiʻekiʻe i hoʻohana pinepine ʻia i nā uea a me nā kaula he mau kukuna electron i hana ʻia e nā mea hoʻolalelale electron. ʻOiai ʻo kēia hoʻopili ʻana e hilinaʻi ana i ka ikehu kino, pili ia i ka hoʻopili kino.

Loaʻa i nā ʻano hana crosslinking ʻekolu i luna nā ʻano a me nā noi like ʻole:

Ke hoʻohālikelike ʻia me ka thermoplastic polyethylene (PVC), loaʻa i ka insulation XLPE nā pono penei:

A. Ua hoʻonui ia i ke kūpaʻa ʻana i ka hoʻololi wela, hoʻomaikaʻi i nā waiwai mechanical i nā mahana kiʻekiʻe, a hoʻomaikaʻi i ke kūpaʻa ʻana i ka haki ʻana o ke kaiapuni a me ka ʻelemakule wela.

B. Ua hoʻonui ia i ke kūpaʻa kemika a me ke kūpaʻa o ka solvent, hoʻemi i ke kahe anu, a mālama pono i ka hana uila mua. Hiki i ka mahana hana lōʻihi ke hiki i 125 ℃ a me 150 ℃. Hoʻomaikaʻi pū ka uea a me ke kaula polyethylene i hoʻopili ʻia i ke kea a me ka polyethylene i hoʻomaikaʻi ʻia i ke kūpaʻa pōkole, a hiki i kona kūpaʻa wela pōkole ke hiki i 250 ℃, no nā uea a me nā kaula o ka mānoanoa like, ʻoi aku ka nui o ka hiki ke lawe i kēia manawa o ka polyethylene i hoʻopili ʻia.

C. Loaʻa iā ia nā waiwai mechanical, pale wai a me ke kū'ē i ka radiation maikaʻi loa, no laila ua hoʻohana nui ʻia ia ma nā ʻano like ʻole. E like me: nā uea pili kūloko no nā mīkini uila, nā alakaʻi motika, nā alakaʻi kukui, nā uea hoʻokele hōʻailona haʻahaʻa no nā kaʻa, nā uea locomotive, nā uea a me nā uea no nā kaʻaahi, nā uea palekana kaiapuni no nā mines, nā uea moana, nā uea no ke kau ʻana i ka mana nukelea, nā uea voltage kiʻekiʻe no ke TV, nā uea voltage kiʻekiʻe no ke ahi X-RAY, a me nā uea hoʻoili mana a me nā uea, a pēlā aku.

He mau pono koʻikoʻi ko nā uea a me nā kaula XLPE i hoʻopaʻa ʻia, akā he mau hemahema ko lākou e kaupalena ana i kā lākou noi:

A. Hana hoʻopili maikaʻi ʻole i ka wela. I ka wā e hana ai a hoʻohana i nā uea ma mua o ko lākou mahana i helu ʻia, he maʻalahi no nā uea ke pipili kekahi i kekahi. I nā hihia koʻikoʻi, hiki iā ia ke alakaʻi i ka hōʻino ʻana o ka insulation a me nā kaapuni pōkole.

B. Kū'ē maikaʻi ʻole i ka hoʻoili wela. I nā mahana ma luna o 200℃, lilo ka insulation o nā uea i palupalu loa. Ke kau ʻia e ka ikaika o waho e ʻomi ana a i ʻole ke kuʻi ʻana, hiki ke hana i nā uea e ʻoki a pōkole.

C. He paʻakikī ke kāohi i ka ʻokoʻa kala ma waena o nā ʻāpana. ʻO nā pilikia e like me nā ʻōpala, ke keʻokeʻo a me nā huapalapala i paʻi ʻia e ʻili ana he mea maʻalahi ke kū mai i ka wā o ke kaʻina hana

ʻO D. ʻO ka insulation XLPE me kahi papa pale wela o 150 ℃ he halogen-free loa ia a hiki ke hala i ka hoʻāʻo kuni VW-1 e like me nā kūlana UL1581, me ka mālama ʻana i nā waiwai mechanical a me nā uila maikaʻi loa. Eia nō naʻe, aia nō kekahi mau bottlenecks i ka ʻenehana hana ʻana a kiʻekiʻe ke kumukūʻai.

3. Nā uea a me nā kaula hao silicone

ʻO nā molekole polymer o ka silicone rubber he mau ʻano kaulahao i hoʻokumu ʻia e nā pilina SI-O (silicon-oxygen). ʻO ka pilina SI-O he 443.5KJ/MOL, ʻoi aku ka kiʻekiʻe ma mua o ka ikehu pilina CC (355KJ/MOL). Hana ʻia ka hapa nui o nā uea a me nā kaula silicone rubber ma o ka extrusion anu a me nā kaʻina hana vulcanization wela kiʻekiʻe. Ma waena o nā uea a me nā kaula synthetic like ʻole, ma muli o kona ʻano molekole kū hoʻokahi, ʻoi aku ka maikaʻi o ka hana silicone rubber i hoʻohālikelike ʻia me nā rubbers maʻamau ʻē aʻe.

A. He palupalu loa ia, he elasticity maikaʻi, ʻaʻohe ʻala a ʻaʻohe mea ʻawahia, ʻaʻole makaʻu i nā mahana kiʻekiʻe a hiki ke kū i ke anu nui. ʻO ka pae mahana hana mai -90 a 300℃. ʻOi aku ka maikaʻi o ke kūpaʻa wela o ka ʻōpala silicone ma mua o ka ʻōpala maʻamau. Hiki ke hoʻohana mau ʻia ma 200℃ a no kekahi manawa ma 350℃.

B. Kūpaʻa maikaʻi loa i ka wā. ʻOiai ma hope o ka lōʻihi o ka hoʻopili ʻia ʻana i nā kukuna ultraviolet a me nā kūlana aniau ʻē aʻe, ua loli iki wale kona mau ʻano kino.

C. He kiʻekiʻe loa ke kū'ē ʻana o ka laholio silicone a kūpaʻa kona kūpaʻa ma luna o nā ʻano mahana a me nā alapine (frequencies).

I kēia manawa, he kūpaʻa maikaʻi loa ka ʻōpala silicone i ka hoʻokuʻu ʻana o ke corona voltage kiʻekiʻe a me ka hoʻokuʻu ʻana o ke arc. Loaʻa i nā uea a me nā kaula i hoʻopaʻa ʻia me ka ʻōpala silicone nā pono i luna a hoʻohana nui ʻia i nā uea hāmeʻa voltage kiʻekiʻe no nā kīwī, nā uea pale wela kiʻekiʻe no nā umu microwave, nā uea no nā mea kuke induction, nā uea no nā ipu kofe, nā alakaʻi no nā kukui, nā lako UV, nā kukui halogen, nā uea pili kūloko no nā umu a me nā mea pā, ʻoi aku hoʻi ma ke kahua o nā lako hale liʻiliʻi.

Eia nō naʻe, ʻo kekahi o kona mau hemahema ponoʻī e kaupalena ana i kāna noi ākea. Eia kekahi laʻana:

A. Palekana haehae maikaʻi ʻole. I ka wā e hana ai a hoʻohana ʻia paha, ua maʻalahi ia i ka hōʻino ʻia ma muli o ka ikaika o waho e ʻomi ana, e ʻānai ana a me ka wili ʻana, kahi e hiki ai ke hana i kahi kaapuni pōkole. ʻO ke ana palekana o kēia manawa, ʻo ia ka hoʻohui ʻana i kahi papa o ke aniani fiber a i ʻole ke fiber polyester wela kiʻekiʻe i ulana ʻia ma waho o ka insulation silicone. Eia nō naʻe, i ka wā e hana ai, pono nō e pale i nā ʻeha i hana ʻia e ka ikaika o waho e ʻomi ana i ka hiki.

B. ʻO ka mea hoʻouluulu e hoʻohana nui ʻia nei i ka hoʻoheheʻe ʻana i ka vulcanization he pālua, ʻelua, ʻehā. Loaʻa i kēia mea hoʻouluulu ka chlorine. Loaʻa i nā mea hoʻouluulu halogen-free piha (e like me ka platinum vulcanizing) nā koi koʻikoʻi no ka mahana o ke kaiapuni hana a he pipiʻi. No laila, i ka wā e hana ai i nā kaula uea, pono e hoʻomaopopo ʻia nā mea aʻe: ʻaʻole pono ke kiʻekiʻe loa ke kaomi o ka huila kaomi. ʻOi aku ka maikaʻi o ka hoʻohana ʻana i ka mea rubber e pale aku i ka haki ʻana i ka wā o ke kaʻina hana, kahi e alakaʻi ai i ke kūʻē ʻana i ke kaomi maikaʻi ʻole.

4. Uea ʻili ethylene propylene diene monomer (EPDM) rubber (XLEPDM)

ʻO ka rubber ethylene propylene diene monomer (EPDM) cross-linked he terpolymer o ethylene, propylene a me kahi diene non-conjugated, kahi i hoʻopili ʻia ma o nā ʻano kemika a i ʻole irradiation. Hoʻohui ka uea insulated rubber EPDM cross-linked i nā pono o ka uea insulated polyolefin a me ka uea insulated rubber maʻamau:

A. Palupalu, maʻalahi, ʻālohilohi, ʻaʻole e pipili i nā mahana kiʻekiʻe, kūpaʻa i ka wā ʻelemakule lōʻihi, a kūpaʻa i nā kūlana ʻino (-60 a 125 ℃).

B. Ke kūpaʻa ʻana o ka ʻozone, ke kūpaʻa ʻana o ka UV, ke kūpaʻa ʻana o ka insulation uila, a me ke kūpaʻa ʻana i ka pala kemika.

C. Ua like ke kūpaʻa o ka ʻaila a me ka mea hoʻoheheʻe me ke ʻano o ka insulation rubber chloroprene maʻamau. Hana ʻia ia e nā lako extrusion wela maʻamau a hoʻohana ʻia ka irradiation cross-linking, he mea maʻalahi ke hana a haʻahaʻa ke kumukūʻai. Loaʻa i nā uea insulated rubber ethylene propylene diene monomer (EPDM) nā pono he nui i ʻōlelo ʻia ma luna a hoʻohana nui ʻia i nā kahua e like me nā alakaʻi compressor refrigeration, nā alakaʻi motika wai ʻole, nā alakaʻi transformer, nā kaula kelepona i nā mines, ka ʻeli ʻana, nā kaʻa, nā mea lapaʻau, nā moku, a me nā uea kūloko o nā mīkini uila.

ʻO nā hemahema nui o nā kaula XLEPDM:

A. E like me nā uea XLPE a me PVC, he haʻahaʻa kona kūpaʻa ʻana i ka haehae.

B. ʻO ka hoʻopili maikaʻi ʻole a me ka hoʻopili ponoʻī e pili ana i ka hiki ke hana ma hope.

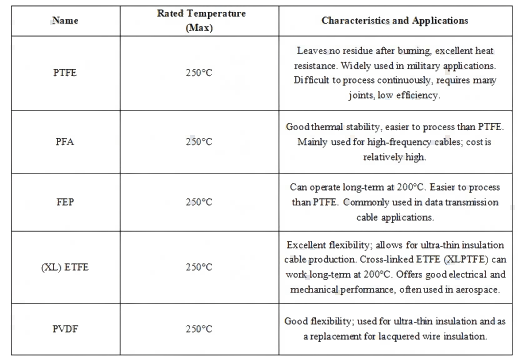

5. Nā uea a me nā kaula Fluoroplastic

Ke hoʻohālikelike ʻia me nā kaula polyethylene maʻamau a me nā kaula polyvinyl chloride, loaʻa i nā kaula fluoroplastic nā hiʻohiʻona koʻikoʻi penei:

A. Loaʻa i nā fluoroplastics kūpaʻa wela kiʻekiʻe ke kūpaʻa wela kupaianaha, e hiki ai i nā kaula fluoroplastic ke hoʻololi i nā wahi wela kiʻekiʻe mai 150 a 250 degere Celsius. Ma lalo o ke kūlana o nā alakaʻi me ka ʻāpana ʻāpana like, hiki i nā kaula fluoroplastic ke hoʻouna i kahi au i ʻae ʻia nui aʻe, no laila e hoʻonui nui ana i ka laulā noi o kēia ʻano uea insulated. Ma muli o kēia waiwai kū hoʻokahi, hoʻohana pinepine ʻia nā kaula fluoroplastic no nā uea kūloko a me nā uea alakaʻi i nā mokulele, nā moku, nā umu wela kiʻekiʻe, a me nā lako uila.

B. Palekana lapalapa maikaʻi: Loaʻa i nā Fluoroplastics kahi helu oxygen kiʻekiʻe, a i ka wā e puhi ai, ua liʻiliʻi ka laulā lapalapa, e hoʻopuka ana i ka uahi liʻiliʻi. ʻO ke kaula i hana ʻia mai ia mea he kūpono ia no nā mea hana a me nā wahi me nā koi koʻikoʻi no ka pale ʻana i ka lapalapa. No ka laʻana: nā pūnaewele kamepiula, nā kaʻaahi, nā kaʻa, nā hale kiʻekiʻe a me nā wahi lehulehu ʻē aʻe, a pēlā aku. Ke puka mai ke ahi, hiki i nā kānaka ke loaʻa ka manawa e haʻalele ai me ka ʻole o ka hāʻule ʻana e ka uahi mānoanoa, no laila e loaʻa ai ka manawa hoʻopakele waiwai.

C. Hana uila maikaʻi loa: Ke hoʻohālikelike ʻia me ka polyethylene, he haʻahaʻa ka dielectric constant o nā fluoroplastics. No laila, ke hoʻohālikelike ʻia me nā kaula coaxial o nā ʻano like, ʻoi aku ka liʻiliʻi o ka attenuation o nā kaula fluoroplastic a ʻoi aku ka kūpono no ka hoʻoili ʻana i nā hōʻailona alapine kiʻekiʻe. I kēia mau lā, ua lilo ka hoʻonui ʻana i ka alapine o ka hoʻohana ʻana i ke kaula i mea maʻamau. I kēia manawa, ma muli o ke kūpaʻa wela kiʻekiʻe o nā fluoroplastics, hoʻohana pinepine ʻia lākou ma ke ʻano he uea kūloko no nā lako hoʻoili a me ke kamaʻilio, nā mea lele ma waena o nā mea hānai hoʻoili uila ʻole a me nā mea hoʻoili, a me nā kaula wikiō a me nā leo. Eia kekahi, he ikaika dielectric maikaʻi ko nā kaula fluoroplastic a me ke kūpaʻa insulation, e kūpono ai lākou no ka hoʻohana ʻana ma ke ʻano he mau kaula hoʻomalu no nā mea hana koʻikoʻi a me nā mika.

D. Nā waiwai mechanical a me nā kemika kūpono: Loaʻa i nā fluoroplastics ka ikehu hoʻopaʻa kemika kiʻekiʻe, ke kūpaʻa kiʻekiʻe, ʻaneʻane ʻaʻole i hoʻopilikia ʻia e nā loli o ka mahana, a loaʻa iā ia ke kūpaʻa maikaʻi loa i ka wā ʻelemakule a me ka ikaika mechanical. A ʻaʻole ia e hoʻopilikia ʻia e nā ʻano waikawa, alkalis a me nā mea hoʻoheheʻe organik. No laila, kūpono ia no nā wahi me nā loli nui o ke aniau a me nā kūlana corrosive, e like me nā petrochemicals, ka hoʻomaʻemaʻe ʻaila, a me ka kaohi ʻana i nā mea hana luawai aila.

E. Hoʻomaʻalahi i nā pilina kuʻihao I nā mea uila, hana ʻia nā pilina he nui ma o ka kuʻihao ʻana. Ma muli o ke kiko heheʻe haʻahaʻa o nā plastics maʻamau, maʻalahi lākou e heheʻe i nā mahana kiʻekiʻe, e koi ana i nā mākau kuʻihao akamai. Eia kekahi, pono kekahi mau wahi kuʻihao i kahi manawa kuʻihao, ʻo ia hoʻi ke kumu i kaulana ai nā kaula fluoroplastic. E like me ke kaula kūloko o nā lako kamaʻilio a me nā mea uila.

ʻOiaʻiʻo, aia nō kekahi mau hemahema o nā fluoroplastics e kaupalena ana i kā lākou hoʻohana:

A. Kiʻekiʻe ke kumukūʻai o nā mea maka. I kēia manawa, hilinaʻi nui ka hana kūloko i nā mea i lawe ʻia mai (ʻo Daikin o Iapana a me DuPont o ʻAmelika Hui Pū ʻIa). ʻOiai ua ulu wikiwiki nā fluoroplastic kūloko i nā makahiki i hala iho nei, hoʻokahi wale nō nā ʻano hana. Ke hoʻohālikelike ʻia me nā mea i lawe ʻia mai, aia nō kahi ʻokoʻa i ke kūpaʻa wela a me nā waiwai piha ʻē aʻe o nā mea.

B. Ke hoʻohālikelike ʻia me nā mea hoʻokaʻawale ʻē aʻe, ʻoi aku ka paʻakikī o ke kaʻina hana, haʻahaʻa ka pono o ka hana ʻana, hāʻule pinepine nā huapalapala i paʻi ʻia, a nui ka pohō, ka mea e kiʻekiʻe ai ke kumukūʻai hana.

I ka hopena, ʻo ka hoʻohana ʻana o nā ʻano mea hoʻokaʻawale i ʻōlelo ʻia ma luna nei, ʻoiai nā mea hoʻokaʻawale kūikawā wela kiʻekiʻe me ke kūpaʻa wela ma luna o 105 ℃, aia nō i loko o kahi wā hoʻololi ma Kina. Inā he hana uea a i ʻole ka hana ʻana i ka uea, ʻaʻole wale kahi kaʻina hana makua, akā he kaʻina hana hoʻi o ka hoʻomaopopo pono ʻana i nā pono a me nā hemahema o kēia ʻano uea.

Ka manawa hoʻouna: Mei-27-2025