ʻO ke au hou o ka ʻoihana kaʻa ikehu hou ke poʻo i ka misionari pālua o ka hoʻololi ʻana o ka ʻoihana a me ka hoʻonui ʻana a me ka pale ʻana i ke kaiapuni lewa, kahi e hoʻokele nui ai i ka hoʻomohala ʻana o ka ʻoihana o nā kaula uila kiʻekiʻe a me nā mea pono ʻē aʻe e pili ana no nā kaʻa uila, a ua hoʻokomo nā mea hana kaula a me nā kino hōʻoia i ka nui o ka ikehu i ka noiʻi a me ka hoʻomohala ʻana i nā kaula uila kiʻekiʻe no nā kaʻa uila. Loaʻa i nā kaula uila kiʻekiʻe no nā kaʻa uila nā koi hana kiʻekiʻe ma nā ʻano āpau, a pono e hoʻokō i ke kūlana RoHSb, nā koi maʻamau flame retardant grade UL94V-0 a me ka hana palupalu. Hoʻolauna kēia pepa i nā mea hana a me ka ʻenehana hoʻomākaukau o nā kaula uila kiʻekiʻe no nā kaʻa uila.

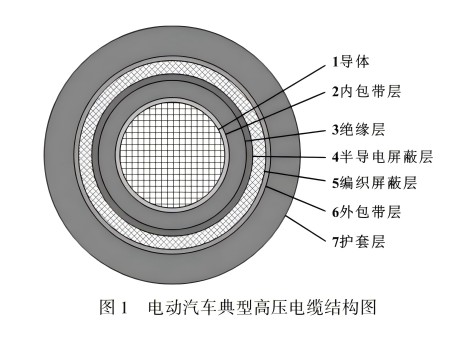

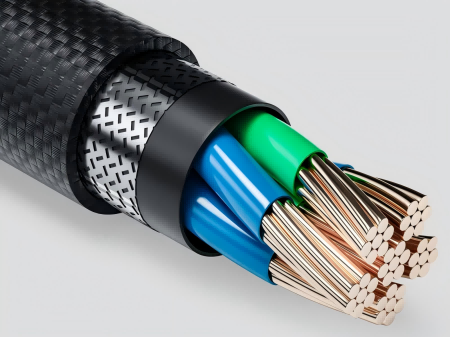

1.ʻO ka mea o ke kaula uila kiʻekiʻe

(1) Mea alakaʻi o ke kaula

I kēia manawa, ʻelua mau mea nui o ka papa alakaʻi kaula: keleawe a me ka alumini. Manaʻo kekahi mau ʻoihana e hiki i ka ʻiʻo alumini ke hōʻemi nui i kā lākou kumukūʻai hana, ma ka hoʻohui ʻana i ke keleawe, ka hao, ka magnesium, ka silicon a me nā mea ʻē aʻe ma ke kumu o nā mea alumini maʻemaʻe, ma o nā kaʻina hana kūikawā e like me ka synthesis a me ka annealing treatment, hoʻomaikaʻi i ka conductivity uila, ka hana kūlou a me ke kūpaʻa ʻana i ka corrosion o ke kaula, i mea e hoʻokō ai i nā koi o ka hiki ke hoʻouka like, e hoʻokō i ka hopena like me nā alakaʻi kumu keleawe a ʻoi aku paha. No laila, ua mālama nui ʻia ke kumukūʻai hana. Eia nō naʻe, manaʻo ka hapa nui o nā ʻoihana i ke keleawe ma ke ʻano he mea nui o ka papa alakaʻi, ʻo ka mea mua, haʻahaʻa ka resistivity o ke keleawe, a laila ʻoi aku ka maikaʻi o ka hapa nui o ka hana o ke keleawe ma mua o ka alumini ma ka pae like, e like me ka nui o ke kahe o ke au, ka pohō haʻahaʻa haʻahaʻa, ka hoʻohana ʻana i ka ikehu haʻahaʻa a me ka hilinaʻi ikaika. I kēia manawa, hoʻohana pinepine ke koho ʻana o nā alakaʻi i ke kūlana aupuni 6 mau alakaʻi palupalu (pono ka elongation uea keleawe hoʻokahi ma mua o 25%, ʻoi aku ka liʻiliʻi o ke anawaena o ka monofilament ma mua o 0.30) e hōʻoia i ka palupalu a me ka paʻakikī o ka monofilament keleawe. Ua papa inoa ka Papa 1 i nā kūlana e pono e hoʻokō ʻia no nā mea alakaʻi keleawe i hoʻohana pinepine ʻia.

(2) Nā mea papa hoʻokaʻawale o nā kaula

He paʻakikī ke kaiapuni kūloko o nā kaʻa uila, i ke koho ʻana i nā mea hoʻokaʻawale, ma ka ʻaoʻao hoʻokahi, e hōʻoia i ka hoʻohana palekana ʻana o ka papa hoʻokaʻawale, ma ka ʻaoʻao ʻē aʻe, e koho i nā mea hana maʻalahi a hoʻohana nui ʻia e like me ka hiki. I kēia manawa, ʻo nā mea hoʻokaʻawale i hoʻohana pinepine ʻia ʻo polyvinyl chloride (PVC).polyethylene i hoʻopili ʻia (XLPE), ka laholio silicone, ka elastomer thermoplastic (TPE), a pēlā aku, a ua hōʻike ʻia ko lākou mau waiwai nui ma ka Papa 2.

I waena o lākou, aia ka PVC i ke kēpau, akā pāpā ka RoHS Directive i ka hoʻohana ʻana i ke kēpau, mercury, cadmium, hexvalent chromium, polybrominated diphenyl ethers (PBDE) a me polybrominated biphenyls (PBB) a me nā mea ʻino ʻē aʻe, no laila i nā makahiki i hala iho nei ua pani ʻia ʻo PVC e XLPE, silicone rubber, TPE a me nā mea ʻē aʻe e pili ana i ke kaiapuni.

(3) Mea pale uwea

Ua māhele ʻia ka papa pale i ʻelua ʻāpana: ka papa pale semi-conductive a me ka papa pale ulana. ʻO ke kū'ē nui o ka mea pale semi-conductive ma 20 ° C a me 90 ° C a ma hope o ka ʻelemakule ʻana he ʻōkuhi loea koʻikoʻi ia e ana i ka mea pale, kahi e hoʻoholo pololei ʻole ai i ke ola lawelawe o ke kaula uila kiʻekiʻe. ʻO nā mea pale semi-conductive maʻamau e komo pū me ka ethylene-propylene rubber (EPR), polyvinyl chloride (PVC), a mepolyethylene (PE)nā mea i hoʻokumu ʻia. I ka hihia ʻaʻohe pono o ka mea maka a ʻaʻole hiki ke hoʻomaikaʻi ʻia ka pae maikaʻi i ka wā pōkole, e kālele ana nā ʻoihana noiʻi ʻepekema a me nā mea hana mea uwea i ka noiʻi ʻana i ka ʻenehana hana a me ka lakio formula o ka mea pale, a e ʻimi i ka hana hou i ka lakio haku mele o ka mea pale e hoʻomaikaʻi i ka hana holoʻokoʻa o ke uwea.

2. Kaʻina hana hoʻomākaukau uwea uila kiʻekiʻe

(1) ʻenehana kaula alakaʻi

Ua lōʻihi ka hoʻomohala ʻana o ke kaʻina hana kumu o ke kaula, no laila aia kekahi mau kikoʻī maʻamau i ka ʻoihana a me nā ʻoihana. I ke kaʻina hana o ke kaha kiʻi uea, e like me ke ʻano wehe ʻana o ke kaula hoʻokahi, hiki ke hoʻokaʻawale ʻia nā lako kaula i ka mīkini kaula wehe ʻana, ka mīkini kaula wehe ʻana a me ka mīkini kaula wehe/wehe ʻana. Ma muli o ke kiʻekiʻe o ka mahana crystallization o ke alakaʻi keleawe, ʻoi aku ka lōʻihi o ka mahana annealing a me ka manawa, he kūpono ke hoʻohana ʻana i nā lako mīkini kaula wehe ʻana e hoʻokō i ka huki mau a me ka huki mau ʻana i ka monwire e hoʻomaikaʻi i ka elongation a me ka haki ʻana o ke kaha kiʻi uea. I kēia manawa, ua pani piha ke kaula polyethylene cross-linked (XLPE) i ke kaula pepa ʻaila ma waena o 1 a me 500kV voltage. ʻElua mau kaʻina hana hana alakaʻi maʻamau no nā alakaʻi XLPE: ka hoʻopaʻa ʻana i ka pōʻai a me ka wili uea. Ma kekahi ʻaoʻao, hiki i ke kumu uea ke pale aku i ke kiʻekiʻe o ka mahana a me ke kaomi kiʻekiʻe i loko o ka pipeline cross-linked e kaomi i kāna mea pale a me ka mea insulation i loko o ka hakahaka uea stranded a hana i ka ʻōpala; Ma ka ʻaoʻao ʻē aʻe, hiki iā ia ke pale aku i ka komo ʻana o ka wai ma ke kuhikuhi o ke alakaʻi e hōʻoia i ka hana palekana o ke kaula. ʻO ke alakaʻi keleawe ponoʻī he ʻano kaula concentric, kahi i hana nui ʻia e ka mīkini kaula kiʻi maʻamau, ka mīkini kaula ʻōpuʻu, a pēlā aku. Ke hoʻohālikelike ʻia me ke kaʻina hana hoʻopaʻa pōʻai, hiki iā ia ke hōʻoia i ka hoʻokumu ʻana o ke kaula alakaʻi i ka pōʻai.

(2) Ke kaʻina hana hana insulation uwea XLPE

No ka hana ʻana o ke kaula XLPE kiʻekiʻe, ʻo ka catenary dry cross-linking (CCV) a me ka vertical dry cross-linking (VCV) ʻelua mau kaʻina hana.

(3) Kaʻina hana hoʻopuka

Ma mua, ua hoʻohana nā mea hana uwea i kahi kaʻina hana extrusion lua e hana i ke kumu insulation uwea, ʻo ka hana mua i ka manawa like pale alakaʻi extrusion a me ka papa insulation, a laila hoʻopili ʻia a ʻōwili ʻia i ka pā uwea, waiho ʻia no kekahi manawa a laila pale insulation extrusion. I ka makahiki 1970, ua ʻike ʻia kahi kaʻina hana extrusion ʻekolu papa 1 + 2 i loko o ke kumu uea insulated, e ʻae ana i ka pale kūloko a me waho a me ka insulation e hoʻopau ʻia i hoʻokahi kaʻina hana. Hoʻopuka mua ke kaʻina hana i ka pale alakaʻi, ma hope o kahi mamao pōkole (2 ~ 5m), a laila hoʻopuka i ka pale insulation a me ka pale insulation ma ka pale alakaʻi i ka manawa like. Eia nō naʻe, he nui nā hemahema o nā ʻano hana mua ʻelua, no laila i ka hopena o nā makahiki 1990, ua hoʻolauna nā mea hoʻolako lako hana uwea i kahi kaʻina hana hana co-extrusion ʻekolu papa, kahi i hoʻopuka ai i ka pale alakaʻi, ka insulation a me ka pale insulation i ka manawa like. I kekahi mau makahiki i hala aku nei, ua hoʻolauna pū nā ʻāina ʻē i kahi hoʻolālā hou no ka poʻo barela extruder a me ka papa mesh curved, ma ke kaulike ʻana i ke kaomi kahe o ke poʻo wili e hōʻoluʻolu i ka hōʻiliʻili ʻana o nā mea, e hoʻolōʻihi i ka manawa hana mau, a me ka hoʻololi ʻana i ka hoʻololi mau ʻana o nā kikoʻī o ka hoʻolālā poʻo hiki ke mālama nui i nā kumukūʻai downtime a hoʻomaikaʻi i ka pono.

3. Hopena

Loaʻa i nā kaʻa ikehu hou nā manaʻolana hoʻomohala maikaʻi a me kahi mākeke nui, pono i kahi moʻo o nā huahana uwea uila kiʻekiʻe me ka hiki ke hoʻouka kiʻekiʻe, ke kūpaʻa wela kiʻekiʻe, ka hopena pale electromagnetic, ke kūlou ʻana, ka maʻalahi, ke ola hana lōʻihi a me nā hana maikaʻi ʻē aʻe i ka hana ʻana a noho i ka mākeke. ʻO nā mea uwea uila uila kiʻekiʻe a me kāna kaʻina hoʻomākaukau he mau manaʻolana ākea no ka hoʻomohala ʻana. ʻAʻole hiki i ke kaʻa uila ke hoʻomaikaʻi i ka pono hana a hōʻoia i ka hoʻohana ʻana i ka palekana me ka ʻole o ke uwea uila kiʻekiʻe.

Ka manawa hoʻouna: Aug-23-2024